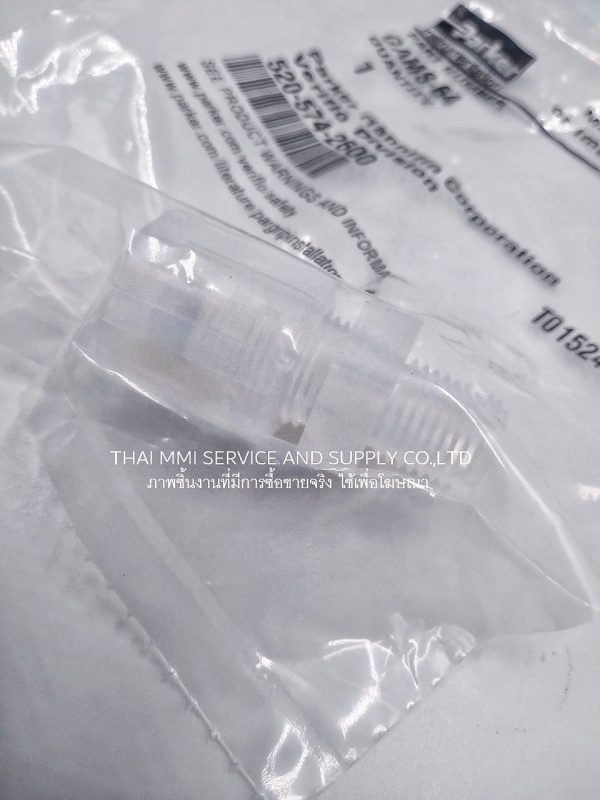

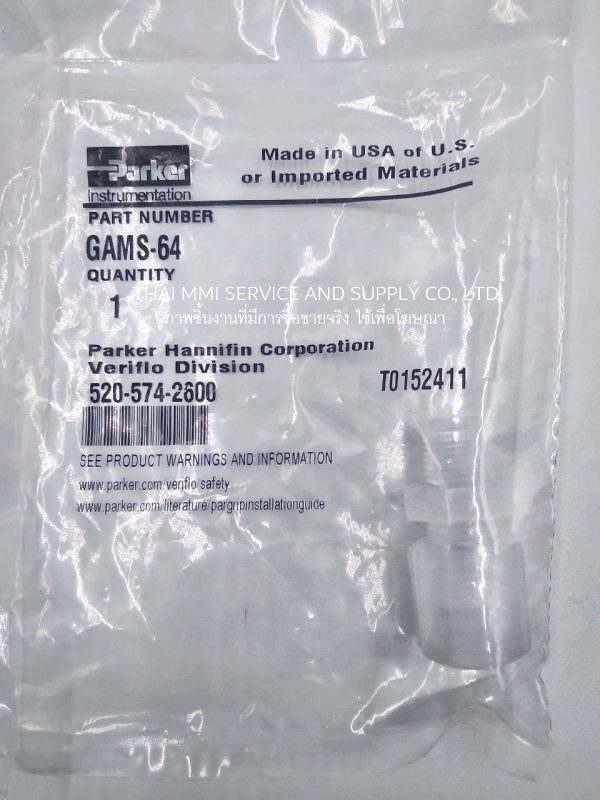

PARKER – Pargrip PFA Tube Fittings

- Description

Description

PARKER – Pargrip PFA Tube Fittings

Manufactured: PARKER

Product Type: PFA Tube Fitting

Series: Pargrip

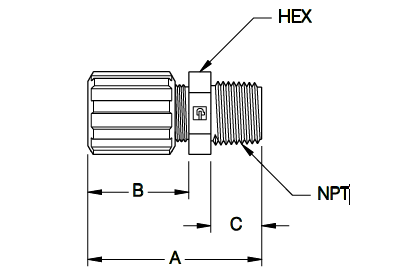

P/N: GAMS-64

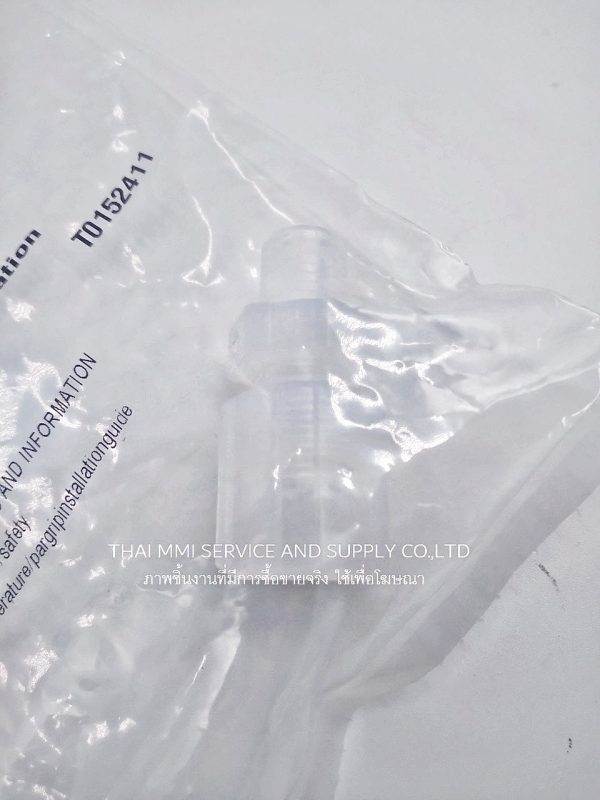

Pargrip PFA Tube Fittings provide a leak tight connection, making them ideal for use in highly corrosive chemical tubing systems. The fittings feature a double ferrule design and are available in a variety of sizes (1/8 to 3/4 inch) and configurations.

Product Description

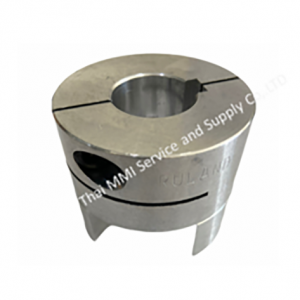

PARKER – Pargrip PFA Tube Fittings are ideally suited for use in highly corrosive environments and chemical handling applications, including process analytical equipment and semiconductor/fab tubing runs. The fittings’ ferrule and ETFE gripper design yields a leak-tight connection, resulting in minimal particle entrapment and high cleanliness.

Pargrip Series tube fittings do not require any special tools for assembly. The connection is achieved by merely inserting the tubing into the fitting assembly and tightening the nut, which significantly reduces installation time and costs. Additionally, the fittings do not require any scoring, which allows for easier remakes than traditional compression fittings.

The PFA tube fittings are available in a variety of sizes (1/8 inch to 3/4 inch) and configurations (reducers, elbows, and tees) to meet the unique requirements of customers’ systems. Many configurations are fitted with Redi-flare end connections, which save space and are ideally suited for use in tight areas, including valve manifold boxes (VMBs).

The exacting design of Pargrip Series fittings, coupled with extremely rugged wetted (PFA, PTFE Ferrule) and non-wetted (PFA nut, ETFE gripper) materials of construction, afford it high performance and reliability at working pressures up to 125 psig.

Assembly Procedure

1. Cut tubing evenly using a tube cutter: TCTR-1 for 1/8” – 1/2” and TCTR-2 for 1/8” – 3/4”.

2. Slip small end of the fitting nut over tubing.

3. Slip small end of the gripper onto tubing.

4. Slip large end of the ferrule onto tubing.

5. Slip tubing into the fitting body until bottomed out.

6. Tighten nut finger tight while assuring that tubing remains seated in bottom of fitting body.

7. Tighten nut at least one additional turn.