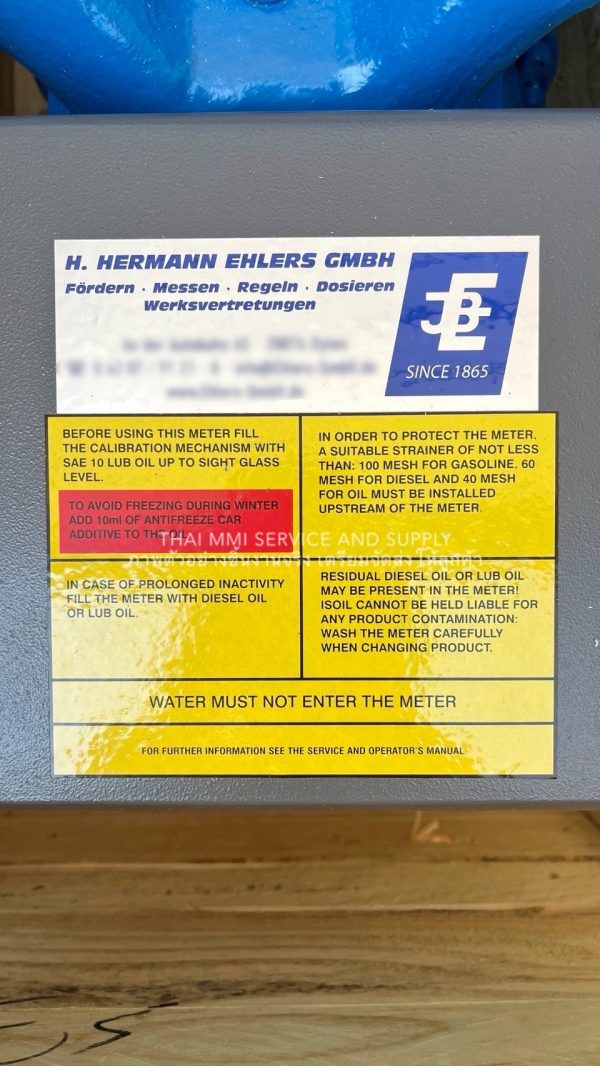

H.HERMANN EHLERS GMBH – Vanemeter BM400

- Description

Description

H.HERMANN EHLERS GMBH – Vanemeter BM400

Manufactured: H.HERMANN EHLERS GMBH

Product: Vanemeter For Fuel Oil

Model: BM400

Positive Displacement Meters (BM 200 – 400 – 600)

ISOIL BM p.d. meters sizes 3″ , 4″ and 6″ grant high accuracy in measurement (+/- 0,1%) and a repeatability of 0,02% over a wide range of flow rates. Correct usage and maintenance ensure this accuracy through long periods of use. Measured flow rate can be displayed on a mechanical ragister or, thanks to a pulse emitter, on an electronic counter

Applications

- Tank, Trucks, Tank wagons and barges loading / unloading

- Aircraft refueling

- Transfer lines

- Calibration of other meters and / or tanks (Master Meter)

Filtering and Air elimination

In order to assure precise measurement and preserve the meter from damage, the fluid under measurement should be properly filtered and air or gas must be eliminated. Strainer air seperators (e.g. ISOIL mod. SFA, SFDA, FDA, DSH, DSV) or stainers (Y stainers) together with air separators (ISOIL mod. DV) are therefore required.

Working Principle

Fluid enters the meter trough the manifold thus exerting pressure on the vanes and rotating the rotor inside the measuring chamber. Here the vanes, made of felf-lubricating material, flow on the internal surface of the the chamber, thus preventing leakage and granting high accuracy in measurement.

Since the measuring chamber has fixed and known volume for each meter type, flowing liquid can be measured.

Thank to a seal mounted on the front cover or to a magnetic drive, a shaft connects rotor movement to mechanical or electronic counter. In this way the number of rotor rotations can be counted and the total amount of fluid is then calculated by multiplying the number of fotor rotations by the volume of the measuring chamber.

Technical Specifications – For Standard Model BM400

EU Directives

- PED: Compliant with Directive 2014/68/UE. Risk category depending on the measure liquid

- ATEX: Non electrical equipment compliant with Directive 2014/34/UE suitable for installation in hazardous area II 2G, Marking Ex II 2 G c Tx

Working conditions

- Flow rate: [200 ; 2,400] L/min @ 10 cSt

- Maximum flow rate avio: 2,600 L/min

- Working pressure: 1,000 kPa max

- Test pressure: 1,700 kPa

- Working temperature: [-30; +100] °C*

Construction

- Manifold and flanges: Carbom Steel

- Body: Carbon Steel with corrosion prevention treatment

- Cover: Carbon Steel with corrosion prevention treatment

- Rotor: Aluminium

- Vanes: Graphite

- Gaskets: Nitrile

- Ball bearing: Stainless Steel

- Seal: Viton lip seal

- Flanges: 4″ ANSI1 50 RF

- Readout (with mechanical register): Liters or m³

- Flow direction: Left

Performances

- Accuracy: (+/-) 0.1%

- Repeatable: 0.02%

Accessories

- Pulse emitter: Encoder EM6422 Ex-d / Pulses emitter EM 345 Ex-i / EM T2 Ex-d inside Veeder Root 7887 register

- VEGA II compensation: Achieved by an algorithm based on “alfa” coefficient or on density

- Unit drum (for Masteer Meter): Allows the reading of 1/10 of the last digit

- Instant flow rate: Mechanical needle indicator

- Ticket printer: Veeder Root. Zero start or cumulative

- Perset: Veeder Root 7889, with one or two pneumatic micro switches or electric Ex-d ATEX micro switches

- Extension for mechanical counter: L. 250 mm. , 500 mm. , 1000 mm. , 3000 mm.

- ISOVALVE automatic valve: 3″ , 4″ or 6″ / 2 stages or Multistep closure / Flow limiting / Non-return